How I cut product waste fast with this ECRS workshop

Being a product manager often feels like juggling a dozen moving parts at once. Roadmaps, stakeholder requests, and daily fires create a whirlwind that can mask inefficiencies and unnecessary complexity. Without a deliberate approach to cutting through the chaos, small process bottlenecks and hidden dependencies quietly pile up, slowing teams down and consuming valuable resources.

Not long ago, we ran an ECRS (eliminate, combine, rearrange, simplify) workshop with our internal customers, engineering, and business teams. It showed me firsthand how structured analysis can uncover hidden waste and streamline processes. The process eliminated redundant steps, redesigned tricky workflows, and turned inefficiencies into clear, actionable improvements.

In this article, I’ll walk you through how I ran my team’s ECRS workshop and give you tips for bringing this method into your day-to-day work, applying its principles to help your team make smarter decisions and design workflows that actually scale.

Why simplification and ECRS matter in product management

Complexity is a hidden tax on time, resources, and focus in product management. Even carefully crafted roadmaps can give the illusion of clarity, but without regular prioritization and customer feedback, they can lead to wasted effort and solutions that don’t solve real problems.

As a PM, your responsibility isn’t just fast delivery — it’s identifying unnecessary processes, cutting complexity, and designing workflows that scale efficiently. Every “if condition” or workaround you add today can become a burden tomorrow. In planning or project analysis meetings, you’ll notice dependencies that complicate delivery.

For example, imagine a project where replatforming issues had to be addressed before the main work could begin, and deadlines were postponed due to domain dependencies. After gathering insights from team leaders, you quickly learn to eliminate unnecessary tasks.

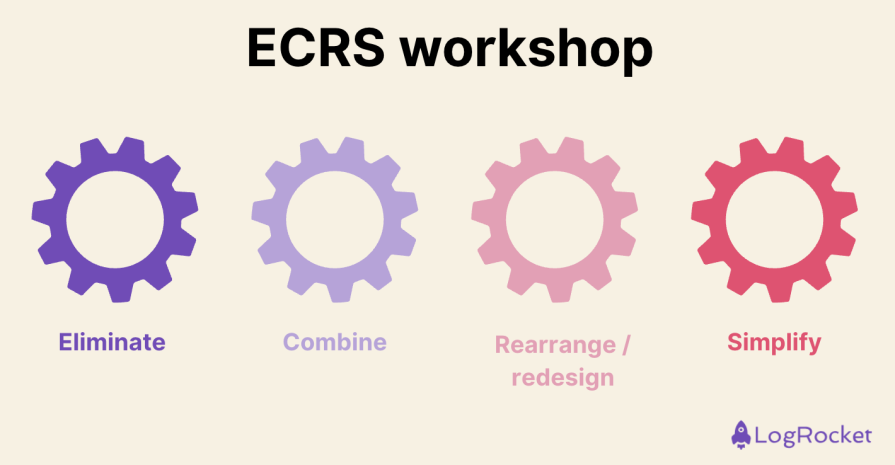

This is where ECRS (eliminate, combine, rearrange, simplify) comes in. Like your KPIs, whether it’s reducing unit time, cutting costs, or saving headcount, ECRS is a practical tool to increase efficiency and productivity with limited resources:

- Eliminate — Remove unnecessary activities from processes

- Combine — Merge tasks to minimize handoffs, transportation, or duplicated work

- Rearrange / redesign — Reorganize or sequence tasks for smoother workflows

- Simplify — Streamline remaining steps to increase efficiency and consistency

By applying ECRS, you not only cut existing complexity but also develop a mindset to prevent future inefficiencies, ensuring your roadmaps and product processes truly create value.

If you blindly follow roadmaps, this article is for you. Stop and focus on simplification first: create “lite mode” options and eliminate waste. Otherwise, the complexity you’ve built will catch up to you.

My team’s ECRS goals: Finding and fixing hidden inefficiencies

As a product team, our goal with ECRS included:

- Identifying differences between locations or teams

- Visualizing and defining best practices to standardize processes and scale improvements across all locations

- Turning potential improvement opportunities into actionable projects, aiming for an X percent reduction in unnecessary effort (UT) across processes

- Driving end-to-end (E2E) process improvements to enhance overall efficiency

- Updating training team audit processes and revising work instructions (WIs) based on best practices

- Generating 10 clear action plans for product teams through field analysis outcomes

PMs often define objectives and problems using standard product management methodologies, but some issues are hidden in small, dusty processes and can be hard to spot. Running an ECRS workshop helps you reveal these hidden inefficiencies.

In fast-growing tech companies, you may rely on lean, agile, or design thinking and wonder if such workshops are old-fashioned. They’re not. ECRS, originally a lean manufacturing method, adapts perfectly to modern product work.

Successful PMs think like a system designer, not just a task juggler. Methods like ECRS teach you to anticipate the complexities your requests may create, avoiding wasted time and resources. These workshops are particularly valuable for teaching both junior and senior PMs that following a fixed product backlog is not always an achievement.

Tips for setting clear team goals in ECRS workshops

Before you determine your team goals, consider these important tips:

- Be specific — Define measurable objectives, like reducing unnecessary effort by X percent or standardizing Y processes

- Align with KPIs — Tie workshop goals directly to product or team KPIs to show clear impact

- Prioritize — Focus on the highest-impact processes first; don’t try to tackle everything at once

- Involve the team — Include diverse perspectives, PMs, CX, UX, business teams to ensure goals reflect real challenges

- Set follow-up actions — Turn insights into concrete action plans with owners and deadlines to track progress

Clear, actionable goals help your team focus on the right processes, measure impact effectively, and ensure that ECRS workshops lead to sustainable, real-world improvements.

Running an ECRS workshop

Running an ECRS workshop might sound intimidating at first, but by breaking it into clear steps, you can systematically identify inefficiencies, engage your team, and uncover opportunities to streamline processes.

Let me walk you through the workshop steps I followed with my team. You can download a basic template for running an ECRS workshop here:

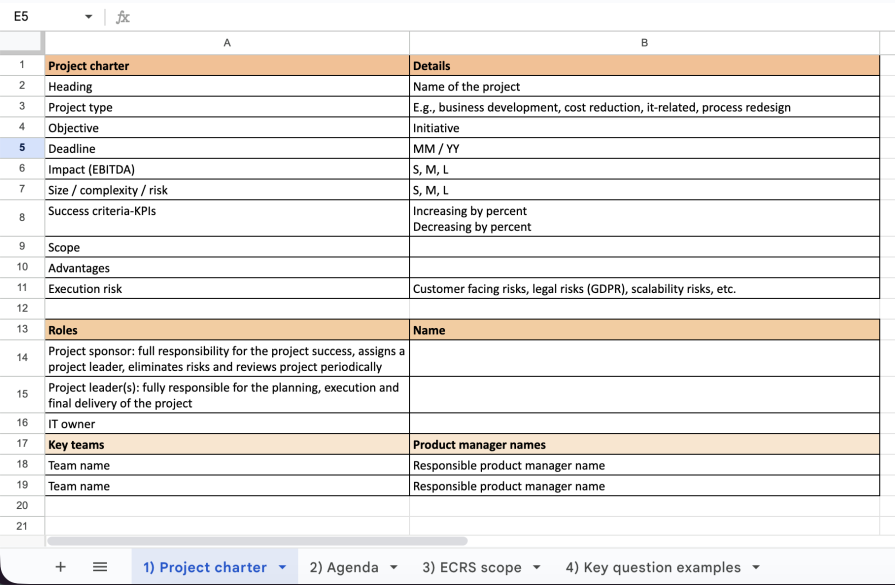

1. Create a project charter

- Start by creating a project charter, just like any other project

- Include essentials: objectives, problem statement, success criteria / KPIs, scoring, and target audience

- Tip for success — Keep it simple at first. Focus on clarity over completeness, you can refine as you go

- Adaptation advice — If your company doesn’t have detailed internal metrics, gather whatever usage data, surveys, or anecdotal feedback you can to define your target audience

2. Select target users and locations

- Identify the areas or user groups to study. In our first workshop, we focused on two high-usage locations

- Within each location, select representative users (e.g., low, medium, and high performers)

- Tip for success — Use metrics like process completion rates, monthly scores, or leader feedback to guide selection. If you lack metrics, spend time observing and interviewing users before finalizing

- Adaptation advice — Your target groups may differ based on product type, team size, or available data. Prioritize meaningful variation rather than perfect representation

3. Define the agenda and assign roles

- Plan the flow of the workshop and assign responsibilities: moderator, video recorder / note taker, PMs, CX, UX, business teams, and selected users

- Tip for success — Clearly communicate roles in advance so everyone knows their responsibilities

- If you’re crowded you can separate those people in groups. But be careful to not skip any role in each group

- Adaptation advice — Depending on team size, some roles can be combined. Even a single PM can facilitate observation if other roles are unavailable

4. Observe the process

- Step into the field and examine the process end-to-end. Recording is optional; observation alone is often sufficient

- Break the process into smaller steps to better understand where inefficiencies lie:

- To be able to find those inefficiencies you need to ask the right questions at the right time

- Tip for success — Be thorough but realistic, focus on high-impact steps first to manage time and cost

- For example, if the user is doing a step you didn’t design while creating the product, you can ask “What is the purpose of this activity?” Later, when you’re analyzing the workshop you can decide if the process needs to be eliminated or redesigned

- Adaptation advice — If a live observation isn’t possible, consider remote sessions, screen recordings, or user journey mapping workshops

5. Analyze each step with ECRS

- Ask for each step — Why does this exist? How can it be eliminated, combined, rearranged, or simplified?

- Collect detailed notes throughout the workshop

- Tip for success — Encourage participants to be honest, no step is sacred. Use sticky notes, digital boards, or shared docs for visibility

- Adaptation advice — For distributed teams, virtual whiteboards or threaded Slack discussions can replicate in-person brainstorming

6. Review findings and create action plans

- After the pilot workshop, classify each step as value-add or non-value-add. Apply the ECRS methodology to prioritize improvements

- Set actionable next steps, assign owners, and schedule follow-up sessions

- Tip for success — Visualize progress with charts or dashboards to communicate impact quickly

- Adaptation advice — Customize the follow-up cadence and format based on team workflow — weekly check-ins, Slack updates, or sprint board reviews can all work

7. Continuous follow-up

- Track KPIs and OKRs for each process. Follow up on action items, update roadmaps, and repeat workshops as new processes or challenges emerge

- Tip for success — Make ECRS a mindset, not just a one-time event. Encourage team members to ask “Eliminate? Combine? Rearrange? Simplify?” regularly.

- Adaptation advice — Integrate ECRS questions into daily stand-ups, retrospectives, or project kick-offs to reinforce a culture of continuous improvement

Following these steps and adapting them to your context ensures that ECRS workshops become a practical, repeatable tool to drive continuous improvement and measurable impact across your product operations.

Key questions to ask during the ECRS process

As you navigate the ECRS process, keep the following questions in mind:

- What (necessity) — Can be asked in the eliminate phase

- What is the purpose of this activity?

- Is it necessary? Why is it necessary?

- Is it possible to eliminate it?

- What else can be done instead?

- What else should be done

- Where (location) — Can be asked when evaluating the work area

- Where is this activity being done?

- Why is it being done there?

- Is the work area appropriately prepared?

- Is the required equipment/tool in the right place? Why is it there?

- Is the work area properly organized?

- Can this activity be done somewhere else?

- Where should it ideally be done?

- Who (person) — Can be asked in the combine phase

- Who is doing this task? Why that person?

- Should we define the required skill level?

- Is the assigned person suitable for the task?

- Who else could do this?

- Who should ideally do it?

- When (timing / sequence) — Can be asked in the rearrange phase

- When should this be done? Why at that time?

- Is this the right time to do it? Why?

- Can it be done before or after other tasks?

- Can it be done during machine/tool operation?

- When else could it be done?

- How (method) — Can be asked in the simplify phase

- How is this done? Why is it done this way?

- Has motion/work efficiency been considered?

- Is it possible to do it differently? How?

- What other ways can it be done?

- How should it ideally be done?

How to apply ECRS weekly as a PM

Running full-scale workshops every week can be costly and time-consuming. However, after conducting a few sessions, the ECRS way of thinking becomes part of your mindset. You don’t always need a formal workshop to apply for it.

Sprint retros, planning or grooming sessions, and new project meetings are perfect opportunities to embed ECRS thinking. You probably won’t have time to run through the full workshop, but you can still ask your team questions like:

- “What else can we do instead?”

- “Is this the right time to do it? Why?”

- “Can this step be simplified or combined with another?”

You can maintain a key question list for each ECRS header (eliminate, combine, rearrange, simplify) and consciously select at least one question to bring up in daily standups, sprint reviews, or project meetings. Over time, these questions will become second nature, helping you spot inefficiencies and potential improvements faster.

ECRS can also be applied when reviewing OKRs, workflows, or feature requests. For example:

- While reviewing a workflow, ask whether a step can be eliminated or automated

- During OKR review, check if a target requires unnecessary effort or duplication

Asking the right questions consistently is one of the most powerful skills for a PM. It doesn’t just uncover inefficiencies, it encourages your team to think critically, question assumptions, and co-create simpler, more effective solutions.

Ultimately, the goal is to turn ECRS into a weekly habit that guides decision-making, reduces unnecessary complexity, and accelerates results.

Results and lessons from my team’s ECRS workshop

After separating value-added, non-value-added, and action-needed processes, we mapped each one to the appropriate ECRS step: eliminate, combine, rearrange, or simplify. This helped us prioritize improvements and decide where to focus first.

Key wins:

- Eliminated unnecessary steps:

- Quality control for certain branded shoes that are already checked by the seller

- Duplicate checking during picking processes, which was already done before shipment

- Unnecessary scans for conveyor assignment, previously required before automatic tote assignment

These removals led to an estimated 15 headcount savings annually, reducing ongoing effort and freeing up team capacity for higher-value work.

- Redesigned processes for better user experience:

- Corrected misrouted packages by improving routing algorithms

- Identified areas where manual sorting added no value and explored automated sorting solutions

- Determined processes suitable for robotic handling to reduce manual effort and errors

Lessons learned:

- Observing processes end-to-end uncovers hidden inefficiencies that aren’t obvious from data alone

- Not all improvements are immediate, some require roadmap planning and staged implementation

- Engaging cross-functional teams ensures both practical feasibility and alignment with operational goals

Carrying forward:

- Improvements identified are now part of our roadmap and are being implemented incrementally according to their impact

- Insights from this workshop are being applied to other locations and workflows to drive consistent efficiency gains

- The ECRS methodology has become a lens for evaluating future processes, helping the team proactively spot complexity and inefficiency

The workshop showed that hands-on analysis combined with structured ECRS thinking doesn’t just improve processes, it also creates a culture of continuous improvement and smarter decision-making across the team.

Final thoughts

Applying ECRS isn’t a one-off exercise, it’s a mindset, a lens through which you continuously evaluate every task, process, and project. From hands-on workshops to weekly standups, sprint retros, and OKR reviews, ECRS questions guide you and your team to challenge assumptions, eliminate waste, and streamline work without losing sight of your objectives.

As a PM, adopting this way of thinking will help you uncover hidden inefficiencies, reduce unnecessary complexity, and ensure that every step your team takes adds real value. Over time, it turns your workflow into a self-improving system, where decisions are guided not by habit or routine, but by clarity, efficiency, and impact.

Remember: complexity is invisible until it becomes a problem. Start asking the right questions today, and let ECRS be your guide to building products and processes that are simple, scalable, and successful.

Featured image source: IconScout

The post How I cut product waste fast with this ECRS workshop appeared first on LogRocket Blog.

This post first appeared on Read More